Indian Economy – Agriculture – FOOD PROCESSING INDUSTRY

Introduction

- Right from the cultivation and harvest of crop, upto the consumption of product by consumer, there is certain degree of value addition in every product. This value addition can be of numerous types.

- As it goes from producer, to wholesaler, to retailer and finally to consumer, every stage adds some value to the product. In this value chain there may be value addition by Sorting, grading, packaging, branding

- These activities makes product attractive, more usable, gives choice and awareness to customers and also enhances shelf life of products. Apart from this service rendered by intermediaries to pass on product from producer to customer is also valuable.

- Most of the agricultural products are not consumable in their original form, for which they are processed. Wheat is converted into flour, Paddy into rice, sugarcane into jagery, Sugar, ethanol, alcohol etc.

- These products can be further processed such as flour into bread. Apart from this, left over part of crop such as risk husk can also be processed to get some useful product for e.g. Rice Bran oil, cattle feed, Sugarcane bagasse can be used for power cogeneration.

- Hence, food processing not merely adds value to the agro products, but also increases their utility. We know that activities in an economy are broadly divided into Agriculture, industry and Services. Food processing Industry is the product of agriculture and Industry.

Significance of food processing industries:

- India is a land famous for food production. More than 50% of Indian population work in Agriculture related activities. If there are good food processing industries in India, raw materials like grains or meat can be converted into food for domestic and foreign consumption.

- Food processing units acts as a link between agriculture and industries.

- Food processing industries can absorb a major share of workers from the agriculture sector, who face disguised unemployment. It can lead to better productivity and GDP growth.

- India’s demographic dividend is much talked about and most of this lies in rural India. Indian youth is turning away from agriculture because of low profitability. FPI is perhaps best bet to seize opportunity of demographic dividend.

- Food processing prevents food wastage and help in attaining food security.

- Processed food requires less space for storage.

- Processed food can be exported. This may help us in getting foreign exchange reserves.

Where India stands?

- The food processing industry is one of the largest industries in India and ranks fifth in terms of production, consumption and exports. As per the latest data available, food processing sector is expected to reach US$ 258 billion in FY15.

- India is largest producer of Pulses, Mangoes, Banana, Milk, ginger, Buffalo meat and 2nd largest producer of rice, wheat, potato, garlic, cashew nut, groundnut, dry onion, green peas, pumpkin, gourds, cauliflowers, sugarcane, and tea in the world.

- We produce 17 per cent of the global total of vegetables and 14 per cent in the case of fruits. About 40 percent of the world’s mangoes and 30 per cent of the world’s bananas and papayas are produced in India. Further, India has many unique things to offer such as Alphonso Mangoes and wheat of Madhya Pradesh is uniquely protein rich.

- India is net exporter of agricultural products. But value addition of Indian product remains quite low. Indian Manufacturers haven’t moved much ahead in value chain. Say If mangoes are processed in to Mango Juice or pulp; it will result in more value addition, industry, employment, GDP and foreign exchange, but we export mainly mangoes as it is.

- Food processing has potential to turnaround whole economy. Indian economy is still agrarian, because about 55% population is directly dependent upon agriculture. FPI directly targets farming sector as it attempts to create more types of products out of single crop. This will increase demand for farmers and hence more remunerative prices.

- Apart from this India’s economy is under transition, Income classes are moving upward. Every year millions of households are coming out of poverty to be part of middle class. Per capita income is Increasing as GDP growth rate is much higher than population growth rate.

- This is complimented by growing urban culture, nuclear families, working couples. This makes case for processed food compelling. Consumption in India is gradually tilting towards packaged and ready-to-eat foods. Demand is bound to increase, but it has to be seen that to what extent opportunity is seized by Indian industry and how much is left for foreign companies.

- FPI is employment intensive industry; it can be an answer to jobless growth of past decade. Currently, only 3 % of employment is in FPI, while in developed countries it handles 14% population. Again, much of the employment will be created into rural India. This can remedy problem of distress migration.

Concerns:

- The biggest bottleneck in expanding the food processing sector, in terms of both investment and exports, is lack of adequate infrastructure. Without a strong and dependable cold chain vital sector like food processing industry which is based mostly on perishable products cannot survive and grow.

- Even at current level of production, farm produce valued at Rs 70,000 million is being wasted every year only because there is no adequate storage, transportation, cold chain facilities and other infrastructure supports.

- An estimated 25% of fruits and vegetables valued at about Rs250bn-300bn is wasted annually due to poor post harvesting technology and inadequate storage and transportation. Cold chain facilities are miserably inadequate to meet the increasing production of various perishable products like milk, fruits, vegetables, poultry, fisheries etc.

- In order to promote the food and allied industries,the Government of India has established, a few national level organisations, which in one way or the other support the industry.

Some of these Institutions are given below.

- Agricultural And Processed Food Products Export Development Authority (Apeda), N. Delhi

- Container Corporation Of India

- Central Food Technological Research Institute, Mysore

- National Seeds Corporation

- Indian Council Of Agricultural Research

- Indian Agricultural Research Institute

- Export Credit Guarantee Corporation Of India Ltd.

- National Horticulture Board

- Etc

Policy Initiatives:

- Government is committed to enhance growth of food processing sector and put it on a robust footing. Government is actively encouraging investment in agro processing industries to reduce wastage and encourage value addition.

- Accordingly, for giving a boost to FPI sector, Government has recently initiated several measures besides tax concessions.

- The major focus of the Ministry aim at increasing Government investment in creating the farm to market supply chain, market processing infrastructure to attract more private investment.

- It is also proposed to strengthen R& D, HRD, in the food processing sector, establish more food testing laboratories to ensure quality of food products and compliance of national & international standards, etc.

Some of the Government Policy Measures:

- As per extant policy FDI up to 100% is permitted under the automatic route in the food infrastructure (Food Park, Cold Chain/warehousing). In so far as food retail is concerned the FDI policy does not permit FDI into Retail sector except Single Brand Product Retailing. This policy is uniform for all retailing activity.

- No industrial license is required for almost all of the food & agro processing industries except for some items like: beer, potable alcohol & wines, cane sugar, hydrogenated animal fats & oils etc.

- MRTP (Monopolies & Restrictive Trade Practices Act) rules and FERA (Foreign Exchange Regulation Act) regulations have been relaxed to encourage investment and expansion by large corporates.

- Most of the items can be freely imported and exported except for items in the negative lists for imports & exports.. Capital goods are also freely importable, including second hand ones in the food processing sector.

- Excise & Import duty rates have been reduced Many processed food items are totally exempt from excise duty. Custom duty rates have been substantially reduced on plant & equipments, as well as on raw materials and intermediates, especially for export production.

- Indian currency (rupee) is now fully convertible on current account and convertibility on capital account with unified exchange rate mechanism is foreseen in coming years.

- Food processing industry is one of the thrust areas identified for exports. Free trade zones (FTZ) and export processing zones (EPZ) have been set up with all infrastructure. Also, setting up of 100% Export oriented units (EOU) is encouraged in other areas. They may import free of duty all types of goods, including capital foods.

- All profits from export sales are completely free from corporate taxes. Profits from such exports are also exempt from Minimum Alternate Tax (MAT)

Agricultural and Processed Food Products Export Development Authority (APEDA)

- APEDA was established by the Government of India under the Agricultural and Processed Food Products Export Development Authority Act 1985.

- The Authority replaced the Processed Food Export Promotion Council (PFEPC).

- APEDA links Indian exporters to global markets besides providing comprehensive export oriented services.

- APEDA provides referral services and suggest suitable partners for joint ventures.

- APEDA’s export basket ranges from typically Indian ethnic products like pickles, chutneys, sauces, curries etc. to rice, honey, fresh and processed fruits and vegetables, beverages, guar gum, poultry, livestock products, confectionery, cut flowers, food grains, aromatic plants and other Indian delicacies.

- Vietnam, UAE, Saudi Arabia, USA, Iran, Iraq and Nepal are the major destinations for export of food products from India.

- APEDA has marked its presence in almost all agro potential states of India and has been providing services to agri-export community through its head office, five Regional offices and 13 Virtual offices.

Composition of the APEDA Authority:

As prescribed by the statute, the APEDA Authority consists of the following members namely:

- A Chairman, appointed by the Central Government

- The Agricultural Marketing Advisor to the Government of India, ex-offical.

- One member appointed by the Central Government representing the Planning Commission

- Three members of Parliament of whom two are elected by the House of People and one by the Council of States

- Eight members appointed by the Central Government representing respectively; the Ministries of the Central Govt.

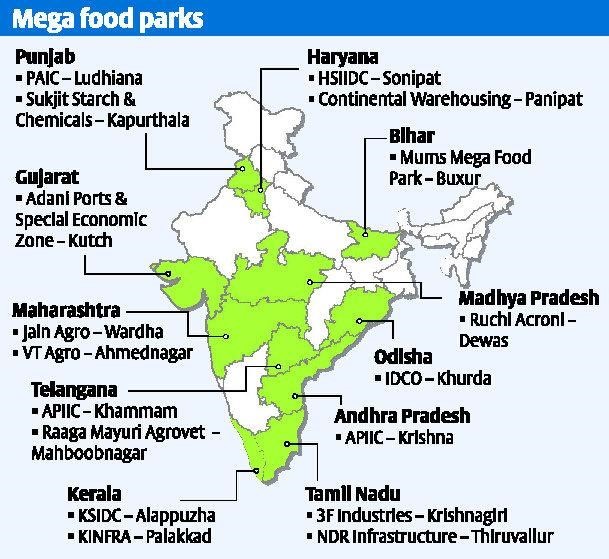

Mega Food Park Scheme

- Mega Food Park scheme is very promising for rural development and integration of rural and urban India through various supply chain linkages. However, the working of the scheme in the last decade paint a different story due to cost overrun, delayed projects and litigated projects. Since land is a state subject therefore success of such scheme is possible only if there is a cooperative federalism and land issues are resolved outside of the court.

- It is a scheme of the Ministry of Food Processing Industry (MOFPI) of the Government of India and is an inclusive concept.

- It proposes a demand driven/pre-marketed model with strong backward/forward linkages and sustainable supply chain.

- Its objective is to establish a “direct linkage from farm to processing and then to consumer markets” through a network of collection centres (CCs) and primary processing centres (PPCs) so as to ensure optimization of value addition, minimization of wastage, increasing farmer’s income and creating employment opportunities particularly in rural sector.

- The scheme is based on a “Cluster” approach and envisages a well-defined agriculture or horticultural-processing zone containing state-of-the art processing facilities with support infrastructure and a well-established supply chain.

Highlights of this scheme

- The financial assistance is provided in the form of grant-in-aid at 50% of eligible project cost in general areas and at 75% of eligible project cost in the North East Region and difficult areas (Hilly States and ITDP areas) subject to maximum of Rs.50 crores per project.

- Collective investment of companies is expected to be at least 250 crores.

- A turnover of 400-500 crores and employment generation of at least 30000 from each mega food park is expected.

- Government has accorded an “infrastructure category” status to the project through this scheme so as to provide incentive for further investment and attract foreign investment.

Modernization of abattoirs:

- The scheme aims at providing facilities for scientific and less painful slaughtering, chilling, effluent treatment plant, by-product utilization, water and power with required sanitary / phyto sanitary conditions for modernization of abattoirs.

- Modernization of abattoirs will also augment essential supply base of hygienic raw material to the meat processing industry, both for domestic consumption and exports, besides discouraging unauthorized slaughtering.

- Scheme of Setting up/ Modernization of Abattoirs provides for induction of private capital, better technology, backward and forward linkages.

- The scheme also provides for implementation of projects preferably under PPP mode with the involvement of local bodies and has the flexibility for involvement of private investors/exporters on a BOO/BOT/JV basis.

Cold Chain Infrastructure :

- Scheme for Integrated Cold Chain, Value Addition and Preservation Infrastructure aims to encourage setting up of cold chain facilities to provide integrated cold chain and preservation infrastructure facilities without break from the farm gate to the consumer.

R&D, QA, Codex and Promotion :

- Scheme for Quality Assurance, Codex, R&D and Other Promotional Activities is being implemented to create infrastructure of food testing laboratories in the country to establish quality monitoring system for food processing, implement HACCP/ISO22000, ISO14000/GHP/GMP and other quality management systems and to promote research and development for innovative products and process etc.

Revolutions related to Food Production and Food Processing

- Pink Revolution– Meat and Poultry Production.

- Red Revolution – Meat & Tomato Production.

- Round Revolution – Potato Revolution.

- Silver Fiber Revolution – Cotton Revolution.

- Silver Revolution – Egg/Poultry Production.

- White Revolution – Milk/Dairy production (Operation Flood).

- Yellow Revolution – Oil Seeds production.

- Evergreen Revolution – Overall development of Agriculture.

- Blue Revolution – Fish Production.

- Brown Revolution – Leather /Cocoa production.

- Golden Fibre Revolution – Jute Production.

- Golden Revolution – Overall Horticulture development/Honey Production.

- Green Revolution – Agriculture in general.

Strength, Weaknesses,Opportunities and Threats :

|

Strengths |

Weaknesses |

|

Round the year availability of raw materials |

High requirement of working capital

|

|

Social acceptability of agro-processing as important area and support from the central government |

Low availability of new reliable and better accuracy instruments and equipments |

|

Vast network of manufacturing facilities all over the country |

Inadequate automation with respect to information management |

|

Vast domestic market |

Remuneration less attractive for talent in comparison to contemporary disciplines |

|

Inadequately developed linkages between R&D labs and industry Opportunities |

|

|

Opportunities |

Threats |

|

Large crop and material base in the country due to agro-ecological variability offers vast potential for agro-processing activities |

Competition from global players |

|

Integration of developments in contemporary technologies such as electronics, material science, computer science, bio-technology etc. offer vast scope for rapid improvement and progress |

Loss of trained manpower to other industries and other professions due to better working conditions prevailing there which may lead to further shortage of manpower. |

| Opening of global markets may lead to export of our developed technology to facilitate generation of additional income and employment opportunities. |

|

The way forward

- Food processing industry has been facing constraints like non-availability of adequate critical infrastructural facilities, like cold chain, packing and grading centres, lack of adequate quality control and testing infrastructure, inefficient supply chain, shortage of processable varieties of farm produce, seasonality of raw material, high inventory carrying cost, high taxation, high packaging cost, affordability and cultural preference for fresh food.

- It is essential to build sustainable supply chains, which will link the farmer to the processing and marketing centres. One of the main reasons for non-development of cold chains in Indian agriculture is the failure to build critical components of the supply chain.

- In the absence of on farm cooling and grading arrangements, the farmer is compelled to sell his produce to the ‘arhtia’ without waiting for a better price. If he is enabled to grade and store his produce close to farm, the farmer will be empowered to demand and obtain a better price from the processors and also add value to his produce.

- Considerable investments are required in rural infrastructure and components of the supply chain by way of grading and packing centres, controlled atmosphere storage facilities, reefer vans, testing laboratories, etc., which may not come from private sources.

- It is, therefore, essential that public investment is significantly increased to fund these components of rural infrastructure to enable private enterprise to take up the remaining components of the supply chain which can be undertaken commercially.

- This is borne out by the experience of developed countries where the State has stepped in to build rural infrastructure in a big way. The failure to direct significant public investment into storage and processing infrastructure, which could then be managed on a public private partnership basis involving all stakeholders, may be the reason for low levels of investment in processing facilities, lack of value addition and the inability of the farmer to obtain better prices and incomes.

- The management of the supply chain is better undertaken with the involvement of all stakeholders on a PPP basis. It is expected that in future bulk investments and modern food processing technologies are going to turn the fortune for Indian food processing industry.

- The sub-sectors such as soft-drink bottling, confectionery manufacture, fishing, aquaculture, grain-milling and grain-based products, meat and poultry processing, alcoholic beverages, milk processing, tomato paste, fast- food, ready-to-eat breakfast cereals, food additives, flavours etc will become the driving force behind the Indian food processing industry.

Conclusion:

- Food processing seems to have promising future, provided adequate government support is there. Food is the biggest expense for an urban Indian household. About 38 % of the total consumption expenditure of households is generally spent on food.

- This share is declining consistently. As mentioned, food processing has numerous advantages which are specific to Indian context. It has capacity to lift millions out of undernutrition. Government has challenge to develop industry in a way which takes care of small scale industry along with attracting big ticket domestic and foreign investments.

Source: www.Reseaerchgate.net